Steel Frame Solutions (SFS)

Coil Steels and Steel Frame Solutions. Two decades of partnership as strong as steel.

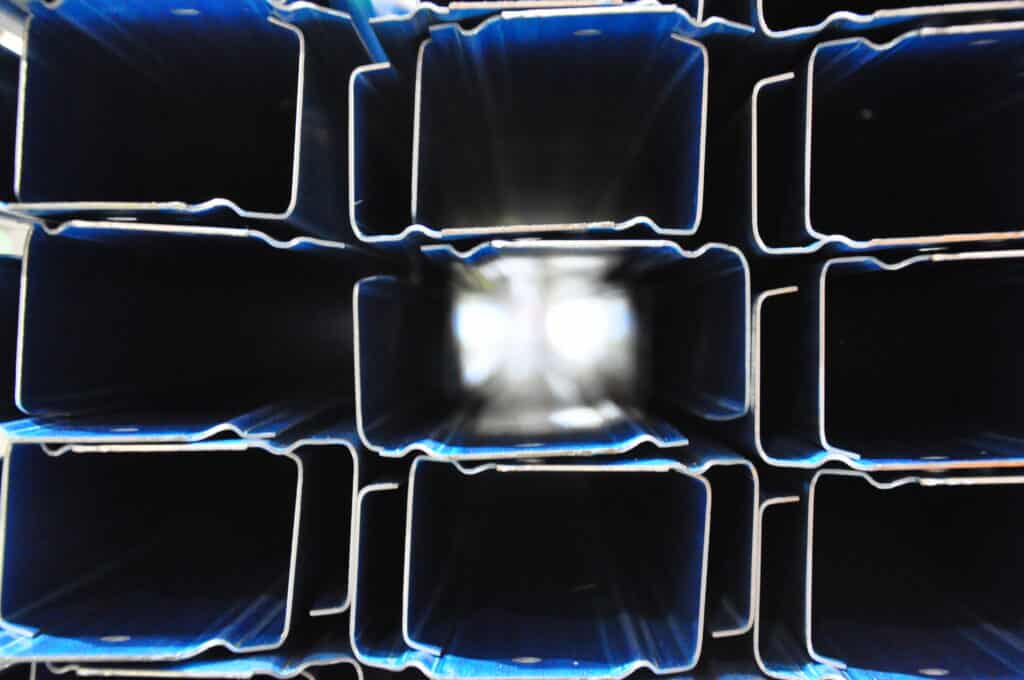

Drive past many residential home builds and there’s a good chance you’ll see Steel Frame Solutions steel frame structures made with TRUECORE® steel. After all, Steel Frame Solutions is one of Australia’s largest manufacturers of pre-fabricated steel wall frames and roof trusses for the commercial and residential building industries.

The revolution in the development of steel framing for residential builds is attributed to John King Senior, Chairman of JG King Building Group, in close partnership with BHP Steel. To this day, John King Senior is regarded as a pioneer in steel frame technology.

Steel Frame Solutions is a division of JG King Building Group, and manufacture and supply steel wall frames, roof trusses, floor systems, battens and accessories for all JG King Homes. That’s roughly 1,000+ homes per year. Steel Frame Solutions also service a range of other builders, both residential and light commerical, with all their framing needs.

As Victoria’s leading steel frame structure manufacturer, it is vital Steel Frame Solutions can rely on their steel supply chain. Coil Steels has been delivering quality steel coil products to Steel Frame Solutions for 20 years, and during that time the two businesses have developed a partnership in steel that has gone from strength to strength.

“We consume a substantial amount of steel. Coil Steels supports our growth through their consistency of product quality, consistency of supply, and price transparency,” explains Marty Phillips, General Manager, Steel Frame Solutions.

“A Steel Frame Solutions house frame, using steel supplied by Coil Steels, offers many benefits, from strength and durability to formability, design flexibility, and sustainability,” notes Dean Manicolo, State Manager Victoria, Coil Steels. “Our Coil Steels team across all levels of our business, take pride in delivering excellence in customer service to Steel Frame Solutions. We take the time needed to really understand what Marty and his team need to deliver for their customers, and we create steel supply options that create value. That is the Coil Steels difference.”

Innovators in steel.

Steel Frame Solutions began using roll forming technology almost 25 years ago in partnership with BHP Steel, as the industries pioneering steel framing business. Over the last 10 years Steel Frame Solutions have partnered with ENDUROFRAME® to develop design solutions for many residential and commercial projects for optimum results. Steel Framed Solutions have been using the ENDUROCADD® software solution, which is a software package that designs and engineers light gauge steel frames, combined with the ENDUROHUB® software to schedule orders and design manuals for sections made from the various rollformers owned by Steel Frame Solutions.

“It has been wonderful to be part of the Steel Frame Solutions journey as a pioneer with light gauge steel frames. Steel Frame Solutions has been a respected member of the steel framing community for many years, supplying thousands of buildings in the 25 years

that we have worked together,” said Warren Tharle Business Development Manager, Enduroframe Building System. “SFS had the vision to pioneer steel framing in its infancy, to work with, train, and nurture carpenters to competently install framing, along with all the following trades. This has been crucial to the success of the steel framing uptake.”

Compliant and flexible steel framing for residential and commercial builders.

Coil Steels supply Steel Frame Solutions TRUECORE® steel in customised slit sizes for various profile ranges, for new residential builds and extensions.

“TRUECORE® steel provides structural integrity in various environments and conditions, with no concerns of shrinking, twisting, or warping,” explains Dean “TRUECORE® steel has a high strength-to-weight ratio combined with its formability enables cost-effective design solutions, reduces material usage, and allows for creative architectural expressions. And the coated protective layer provides exceptional corrosion resistance.”

Steel products supplied by Coil Steels play a huge role in Steel Frame Solutions

exceeding their customer’s quality and service expectations. Steel Frame Solutions are a complete structural solutions business, providing support from the start right through to completion. The entire workforce take a meticulous approach and ensure all frames comply with Australian Standards and the Building Code of Australia.

“We aim to be a compliant and agile flexible solutions provider to volume residential builders, light commercial and anything else requiring steel framing. It’s all about understanding our customer requirements and ensuring we work within our capabilities,” Marty explains.

“Our rollformer capability means that we can offer not just a fully engineered structure, but a range of individual components that others can use as part of their design,” Marty says.

“Steel Frame Solutions has been a respected member of the steel framing community for many years, supplying thousands of buildings in the 25 years that we have worked together.”

“For example, we roll our own steel floor systems in C300 joists and they can be rolled to order and sold externally to replace timber laminated veneer lumber beams. People want steel beams either from a cost and supply perspective, or simply just for the straightness and durability. We can supply a beam that’s a direct like-for-like replacement for span and load capacity from the laminated veneer lumber.”

A strong partnership steeped in trust and reliability.

Coil Steels ensures we always have a significant inventory of TRUECORE® steel on our floor so we can offer fast turnaround for our customers. With our processing capabilities we offer Steel Frame Solutions custom sizes and tailored supply arrangements.

“Coil Steels are our partner and are very responsive to our stock levels to ensure there’s no interruption to supply and production during peak periods,” explains Marty “Stock is consumed and reconciled weekly. Steel Frame Solutions promise to deliver to site within 6 weeks for single storey projects or within 8 weeks for double storey projects. It’s all pre- fabricated and ready to go. We also offer an installation capability for our customers to add value to their build process.”

Dean goes on to explain “Coil Steels barcode labels allow fast and accurate onsite weekly stock level checks. What’s more, the pre-delivery master file ensures Steel Frame Solutions know the exact coils they will receive by size, batch and weight.”

Steel Frame Solutions also rely on Coil Steels for technical support. “We very rarely have any quality issues, and if we do, Coil Steels are supportive and quick to solve problems,” Marty says.

Another key factor in the partnership is the updates Coil Steels provides about trends impacting the industry. Marty explains “We don’t have to invest our time looking at global steel trends because Coil Steels do it for us.”

A long history supporting the community.

Founder of JG King Homes, John G. King has a long history of generosity and giving back to the local community that spans more than three decades. Wherever possible John taps into the network of suppliers and sub-contractors to build houses that are either auctioned off by a charity or providing immediate housing needs for clients.

JG King Homes also proudly donate $100,000 each year to support cancer researchers at the Fiona Elsey Cancer Research Foundation. The company also has a strong interest in supporting local community events.

“Coil Steels supports our growth through their consistency of product quality, consistency of supply and price transparency.”

Marty Phillips, General Manager, Steel Frame Solutions.

“Steel Frame Solutions has been a respected member of the steel framing community for many years, supplying thousands of buildings in the 25 years that we have worked together.”

Marty Phillips, General Manager, Steel Frame Solutions.

“Coil Steels ensures we always have a significant inventory of TRUECORE® steel on our floor so we can offer fast turnaround for our customers.”

Marty Phillips, General Manager, Steel Frame Solutions.

New and emerging applications of steel framing.

For 20 years, the partnership between Coil Steels and Steel Frame Solutions has gone from strength to strength. “It has been fantastic to be a part of the Steel Frame Solutions journey and

we’re excited about the next phase. We are proud to be a major partner of Steel Frame Solutions who embraced light gauge steel framing from the very beginning. There is much more to look forward to on this journey and the light gauge steel framing future is in safe hands with Steel Frame Solutions,” explains Dean.

As Steel Frame Solutions look to the future, Marty says “We’re constantly growing, evolving and improving our processes and looking at new applications and emerging technologies. Right now we’re working with a number of clients on supply solutions who are moving rapidly into modular and tiny houses. Those types of homes are gaining in popularity, particularly with the housing crisis. Customers are seeing the benefit of coming to us – a reputable, stable and compliant business – and using our steel frames. And we’re 100% committed to continuing to partner with Coil Steels and their ability to deliver TRUECORE® steel.”