Coated Sheet & Coil Products Supplied and Processed by Coil Steels

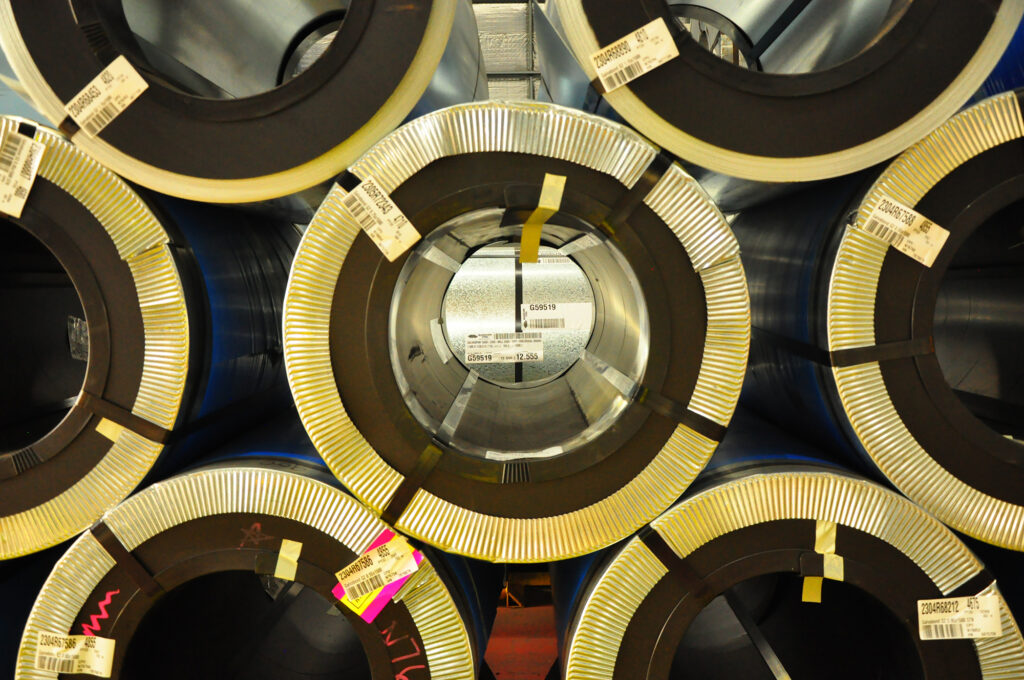

Coil Steels supply the range of BlueScope manufactured coated sheet and coil products, as well as other product options from our carefully selected supply partners, and with our in-house processing equipment our team can supply these products in both sheet and coil form to suit our customers needs.

These coated steel products go into a wide range of end-use applications. Coil steels work closely with our customers to understand their manufacturing and fabrication requirements, and deliver the product needed to meet project timeframes.

Coated steel sheet and coil products are used in a wide range of applications including residential building sections, roofing, walling, tube-formed products, purlins, air conditioning ducts and panels, meter boxes, trailers, scaffolding, planks, coolroom panels, steel framing, switchboards, the list goes on. Also supplied in a wide range of thicknesses, widths, and lengths to suit manufacturing processes.

Coil Steels supplies coated steel products conforming to relevant Australian Standards to meet specific manufacturing requirements. With our in-house shearing services, Coil Steels can also cut to length steel coil to a range of steel sheet sizes to maximise our customers’ manufacturing efficiencies.

Our coated steel sheet and coil range comprises:

- GALVABOND® steel

- GALVASPAN® steel

- Electro Galvanised Steel

- ZINCALUME® steel

- ZINCANNEAL® steel

- ZINC HI-TEN® steel

- ZINCFORM® steel

- DECKFORM® steel

- TRUECORE® steel

GALVABOND® Sheet and Coil Products Supplied and Processed by Coil Steels

Commonly used in commercial and general manufacturing applications, GALVABOND® steel is widely recognised for its appealing spangled surface. GALVABOND® steel offers guaranteed minimum elongation properties and is designed for forming and moderate drawing applications. Available in two grades including G2 and G2S, GALVABOND® steel is produced using a continuous hot dip zinc-coating process with a range of different coating classes.

The product is suitable for moderate drawing applications and is suitable for lock seaming up to 1.6mm thick. GALVABOND® steel G2S is skinpassed to improve surface quality. Under normal storage conditions, free of fluting for 3 months after galvanising. GALVABOND® steel products are available in a range of thickness options – conforming to relevant Australian Standards AS/NZS 1365:1996 (R2016) and AS 1397:2021.

GALVABOND® steel is used in the manufacture of many products, such as partition walling systems, air conditioning ducts and panels, tube, meter boxes, trailers, cable trays, scaffolding planks, rendering mesh, and feeder troughs. With Coil Steels, customers can source all their GALVABOND® steel sheet and coil products to suit their project needs.

Offering the following key benefits, GALVABOND® steel supplied by Coil Steels and made locally by BlueScope:

- Coating

GALVABOND® steel is coated with a layer of zinc, which provides excellent corrosion resistance. The zinc coating acts as a protective barrier, preventing the underlying steel from coming into direct contact with moisture or corrosive elements.

- Durability

The zinc coating enhances the durability of GALVABOND® steel, making it highly resistant to rust and corrosion. This makes it a suitable choice for outdoor applications, where the material is exposed to environmental elements such as rain, humidity, and saltwater.

- Formability

GALVABOND® steel maintains its formability even after the zinc coating process. It can be easily bent, shaped, and formed without compromising the integrity of the coating. This makes it versatile and suitable for various manufacturing processes, including roll forming, bending, and welding.

- Cost-Effectiveness

GALVABOND® steel offers cost-effective protection against corrosion. By applying a zinc coating to the steel, it significantly extends the lifespan of the material, reducing the need for frequent maintenance and replacement. This can result in long-term cost savings, especially in applications exposed to harsh or corrosive environments.

- Sustainability

GALVABOND® steel is a sustainable choice due to its durability and recyclability. The zinc coating can be recycled and reused, reducing the environmental impact of the material. Additionally, the extended lifespan of GALVABOND® steel means less frequent replacements, further reducing waste.

GALVASPAN® Sheet & Coil Products Supplied and Processed by Coil Steels

GALVASPAN® steel is typically used in roll-formed sections used in building products, such as purlins and girts for structural applications. Coil Steels supplies our customers with GALVASPAN® steel coils for their manufacturing processes.

GALVASPAN® steel is a hot-dipped zinc-coated structural steel product, designed for use in commercial and industrial buildings, GALVASPAN® steel is available in Z350 and Z450 coating classes. GALVASPAN® steel is strong, durable, and highly corrosion resistant with a guaranteed minimum yield strength of 450MPa, 500MPa, or 550MPa across a range of thicknesses – conforming to the relevant Australian Standards AS/NZS 1365:1996 (R2016) and AS 1397:2021.

Offering the following key benefits, GALVASPAN® steel is supplied by Coil Steels, and manufactured locally by BlueScope:

- Coating

GALVASPAN® steel is coated with a layer of zinc, providing exceptional corrosion resistance. The zinc coating acts as a protective barrier, shielding the underlying steel from moisture and corrosive elements, ensuring its longevity.

- Structural Integrity

GALVASPAN® steel is known for its structural strength. It is manufactured with high tensile steel, which means it has excellent load-bearing capabilities and structural integrity.

- Durability

The zinc coating on GALVASPAN® steel enhances its durability, making it highly resistant to rust and corrosion. It can withstand harsh environmental conditions, such as exposure to moisture, rain, and chemicals, without significant degradation. This longevity reduces the need for frequent maintenance and replacements.

- Formability

GALVASPAN® steel retains its formability despite the zinc coating. It can be easily manipulated, bent, and shaped without compromising its structural properties. This makes it versatile for different construction and fabrication processes, allowing for custom designs and configurations.

- Cost-Effective

GALVASPAN® steel provides long-term cost savings due to its durability and low maintenance requirements. Its corrosion resistance and structural strength reduce the need for frequent repairs or replacements, leading to reduced overall costs over the lifespan of the structure or application.

- Sustainability

GALVASPAN® steel is an environmentally friendly choice. It is made from recycled steel and is fully recyclable at the end of its lifespan. Additionally, its durability minimizes the consumption of resources and reduces waste over time.

Electro Galvanised Sheet and Coil Supplied and Processed by Coil Steels

Through our supply partners, Coil Steels can source your electro galvanised steel products to suit your manufacturing requirements. Electro galvanised steel is a product that has a corrosion-resistant zinc coating applied to one or both of its sides. This is done by a process called electro deposition and produces a product that has high corrosion resistance and performs well during manufacturing.

Typically used in commercial applications, or where the surface quality after painting needs to be high quality. Office furnishings and light fixtures, automotive panels and electronic equipment, acoustic ceilings, door frames, and switchboards all have applications for electro gal steel. Electro galvanised steel is carbon steel that is spangle free, welds easily, and has good paintability.

ZINCALUME® Sheet & Coil Products Supplied and Processed by Coil Steels

Coil Steels supplies and processes high-quality ZINCALUME® steel products in both sheet and coil form, catering to various manufacturing processes. The Coil Steels team works with our customers to understand your business needs and assist in determining the most suitable ZINCALUME® steel options for your specific applications and project requirements.

The ZINCALUME® steel range offers a selection of grades carefully designed to offer a durable product that uses BlueScope’s Activate® technology to slow the rate of corrosion and offer long-lasting protection. The Coil Steels team is experienced with the ZINCALUME® range, our team can assist customers in choosing the ZINCALUME® product that best meets your manufacturing needs.

Our Coil Steels team is highly experienced at supplying and processing ZINCALUME® steel products. All ZINCALUME® steel products adhere to the relevant Australian standards AS/NZS 1365:1996 (R2016) and AS 1397:202.

Here are some examples of ZINCALUME® steel with Activate® technology grades available:

- ZINCALUME® steel with Activate® technology G250 typically used in general manufactured articles and structural sections.

- ZINCALUME® steel with Activate® technology G300 typically used in general manufactured articles, garage doors and curved roofing.

- ZINCALUME® steel with Activate® technology G450 typically used in structural sections.

- ZINCALUME® steel with Activate® technology G500 typically used in structural sections, house framing, patio posts.

- ZINCALUME® steel with Activate® technology G550 typically used in roofing, walling and structural sections.

- ZINCALUME® steel with Activate® technology G2N typically used in pressed garage door panels.

Offering the following key benefits, ZINCALUME® steel is supplied by Coil Steels in sheet or coil form to customer specifications:

- Corrosion Resistance

ZINCALUME® steel is coated with a combination of zinc, aluminium, and magnesium alloy, providing exceptional corrosion resistance. The aluminium in the coating acts as a protective barrier, preventing the underlying steel from direct contact with corrosive elements. This makes ZINCALUME® steel highly durable and suitable for applications in diverse environments, including coastal areas where salt spray is prevalent. - Enhanced Aesthetic Appeal

ZINCALUME® steel features a distinct metallic silver finish that adds an attractive aesthetic to buildings and structures. This modern appearance allows for versatile design possibilities and architectural flexibility. - Thermal Efficiency

ZINCALUME® steel exhibits excellent thermal performance. The reflective properties of the metallic coating contribute to reducing heat absorption, thus helping to keep the interiors of buildings cooler in hot climates. This can lead to energy savings by reducing the need for excessive air conditioning. - Lightweight and High Strength

ZINCALUME® steel is a lightweight material that offers high strength. This combination makes it easier to handle during installation and reduces structural weight, allowing for cost savings and design flexibility. - Longevity and Durability

ZINCALUME® steel is renowned for its long lifespan and durability. The coating provides excellent resistance against corrosion, ensuring the material’s longevity and reducing maintenance requirements over time. ZINCALUME® steel is designed to withstand harsh weather conditions, including extreme temperatures, UV exposure, and heavy rainfall. - Environmentally Friendly

ZINCALUME® steel is fully recyclable at the end of its lifespan. Its long lifespan and resistance to corrosion reduce the need for replacement, resulting in a reduced environmental impact compared to other materials. - Compliance

ZINCALUME® steel products conform to the appropriate Australian Standards for thickness, mechanical properties, coating mass, and other specifications. This ensures that the material meets rigorous quality and performance requirements. - Termite and Fire Resistance

ZINCALUME® steel is non-combustible, contributing to improved fire safety in buildings. It is also resistant to termites, eliminating the risk of structural damage caused by these pests.

ZINCANNEAL® Sheet & Coil Products Supplied and Processed by Coil Steels

ZINCANNEAL® steel is specifically manufactured with a spangle-free surface making it ideal for powder coating. It is designed to meet the diverse requirements of the manufacturing and automotive segments and Coil Steels has the experience to supply our customers with the ZINCANNEAL® steel products they need.

ZINCANNEAL® steel has excellent bending, roll forming, welding, and painting features. This makes ZINCANNEAL® steel suitable for fabrication processes, ensuring optimal performance. It is commonly utilised in applications that involve forming and moderate drawings, such as electrical cabinets, non-exposed automotive panels, office furniture, washing machines, acoustic ceiling tiles, door frames, commercial refrigerators, freezers, and switchboards.

ZINCANNEAL® steel is available in the grade G2S, which is a hot-dipped zinc/iron alloy-coated commercial forming steel featuring a skin-passed smooth matte surface, ideally suitable for direct-on painting. It is offered in various thickness options for a ZF100 normal coating class or ZF80 coating class (optional).

ZINCANNEAL® steel G2S adheres to the relevant Australian Standards, including AS/NZS 1365:1996 (R2016) and AS 1397:2021, ensuring compliance with established industry specifications and quality standards.

Coils Steels provides processing and project management services to meet the specific requirements of our customers. With extensive experience, the Coils Steels team is capable of handling even the most complex project needs.

Our network of distribution sites ensures easy accessibility and complete supply chain solutions for ZINCANNEAL® steel sheet and coil. We work closely with our customers, assisting in managing product requirements and forecasting to ensure the timely availability of sheet and coil products. The Coil Steels team is here to support you with scheduling, forecasting, consignment options, product labeling, and comprehensive project management from inception to completion.

Offering the following key benefits, ZINCANNEAL® steel is supplied by Coil Steels, and manufactured locally by BlueScope:

- Corrosion Resistance

ZINCANNEAL® steel is coated with a zinc/iron alloy, providing excellent corrosion resistance. The combination of zinc and iron in the coating enhances the material’s ability to withstand rust and corrosion, ensuring long-lasting performance in various environments. - Paintability

ZINCANNEAL® steel is specifically designed for post-painting and powder coating applications. Its spangle-free surface allows for smooth and even paint adhesion, resulting in a high-quality finish. This makes it suitable for applications where a painted or coated surface is desired. - Formability and Fabrication

ZINCANNEAL® steel is engineered to exhibit excellent bending, rollforming, welding, and painting characteristics. It can be easily formed, shaped, and fabricated to meet specific project requirements. This flexibility allows for the creation of complex shapes and designs with precision. - Versatility

ZINCANNEAL® steel finds applications in a wide range of commercial and manufacturing sectors. It is commonly used in automotive panels, electrical cabinets, office furniture, appliances (such as washing machines and commercial refrigerators), door frames, acoustic ceiling tiles, and switchboards, among other applications. Its versatility makes it suitable for both interior and exterior applications. - Compliance

ZINCANNEAL® steel conforms to the relevant Australian Standards, including AS/NZS 1365:1996 (R2016) and AS 1397:2021, ensuring that it meets stringent quality and performance requirements.

ZINC HI-TEN® Sheet and Coil Supplied and Processed by Coil Steels

ZINC HI-TEN® steel products are typically used in the manufacture of products such as purlins, structural decking and scaffolding. Specifically designed with guaranteed yield strengths and excellent welding and painting, ZINC HI-TEN® steel ensures your light-gauge structural needs are covered.

Coil Steels can supply your ZINC HI-TEN® steel products in the form you require, with our in-house processing services, to help make your manufacturing lines efficient. Available in G450, G500 or G550 steel grades, ZINC HI-TEN® steel is a hot dipped zinc-coated structural steel with a spangled or minimised-spangled surface.

Available with a thickness range of 0.3mm to 3.5mm (depending on grade) and a standard coating mass of Z275, with other coating mass options available by inquiry including Z200, Z450, and Z600, all designed to meet your corrosion resistance requirements. Skin pass is optional to improve surface quality depending on the application. ZINC HI-TEN® steel conforms to the relevant Australian Standards AS/NZS 1365:1996 (R2016) and AS 1397:2021.

ZINCFORM® Sheet and Coil Supplied and Processed by Coil Steels

Designed to provide good ductility suitable for rollforming, ZINCFORM® steel is a zinc-coated structural steel product. Excellent bending, rollforming, weldability, and painting performance are all benefits of ZINCFORM® steel, making it ideal for use in the building, construction, and infrastructure segments. Products such as culverts, nail plates, and roll-formed structural sections are typically produced using ZINCFORM® steel.

Coils Steels can supply customers with a range of ZINCFORM® steel products, the range comes in G250, G300, G350, and G400 steel grades with a thickness range between 0.3mm to 3.2mm and a range of standard coating classes. A hot-dipped zinc-coated structural steel with a spangled surface, ZINCFORM® steel can be skin passed as an option to improve surface quality. ZINCFORM® steel conforms to the relevant Australian Standards AS/NZS 1365:1996 (R2016) and AS 1397:2021.

DECKFORM® Sheet and Coil Supplied and Processed by Coil Steels

Through our supply partners, Coil Steels can source your DECKFORM® steel products to suit your manufacturing requirements. Manufactured locally by BlueScope, DECKFORM® steel is a zinc-coated hi-tensile product specifically designed for use in structural formwork and steel decking applications in the building and construction industry. Proper design, specification, and installation of decking made from DECKFORM® steel will ensure many years of effective service.

DECKFORM® steel delivers excellent durability and corrosion protection and is available in a wide range of decking profiles from leading manufacturers. Steel decking products made from DECKFORM® steel are suitable for use in a variety of formwork and composite slab applications including commercial buildings and multi-level car parks as well as residential construction and provide excellent strength and project efficiencies.

DECKFORM® steel conforms to relevant Australian Standards AS/NZS 1365:1996 (R2016) and AS 1397:2021 and is backed by BlueScope warranties based on the zinc coating mass.

TRUECORE® steel Supplied and Processed by Coil Steels

TRUECORE® steel products are utilised in the manufacture of steel framing products, often used in residential housing and multi-storey construction projects. Also used commercial building projects such as educational buildings and healthcare facilities TRUECORE® steel more than delivers. With convenient distribution locations throughout Australia, the experienced team at Coil Steels specialises in supplying TRUECORE® steel coil products to customers who roll-form light gauge steel frame building products. With our state-of-the-art in-house steel slitting services, Coil Steels supplies TRUECORE® steel in coils slit to the most efficient manufacturing sizes to suit our customers’ roll-forming processes. We understand delivering our customers their TRUECORE® steel coils on time keeps their manufacturing processes running.